The physical road allowing access to utilities in energy and telecom is nearly as crucial as their existence. Without access to vital community infrastructure for service, repair, and distribution, utilities become useless. Reiss Earthworks specializes in constructing access roads for towers, wind, solar, gas, and oil utilities across the Midwest. This ensures the effective development and maintenance of these sites, enabling utility experts to quickly access them 24/7/365. Improved access to utilities translates to better public service, and Reiss Earthworks is dedicated to this mission.

Access Road Development and Maintenance

Access roads play a crucial role in facilitating vehicular access to utility sites, including compounds, towers, command centers, anchors, wellheads, solar arrays, gas infrastructure, and wind turbines even in remote or hard-to-reach locations. Whether the site is flat or incredibly steep, we have the operators and heavy machinery available to “pave the path to success.”

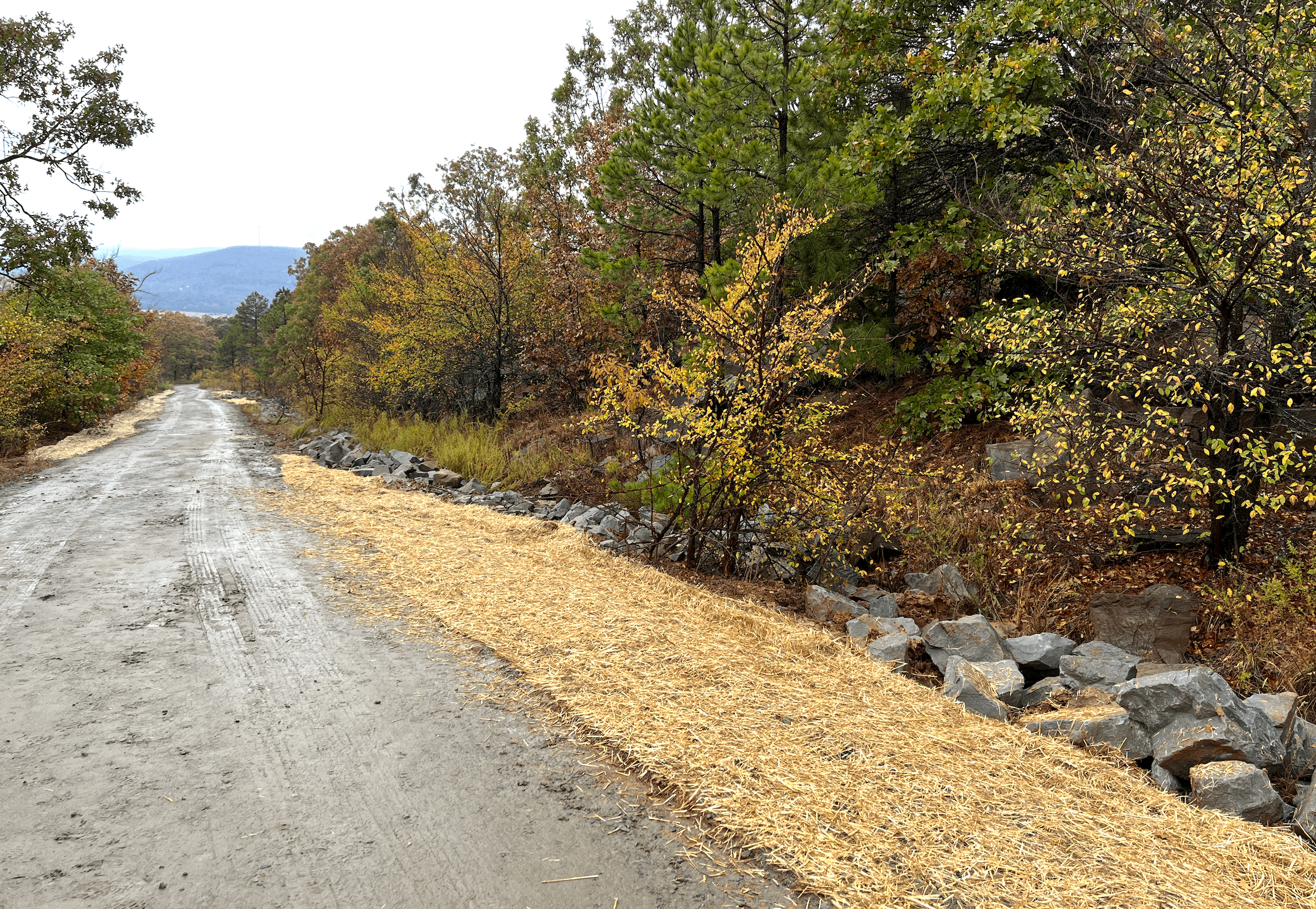

Typically covered with crushed stone, aggregate, rock, or gravel, these roads are essential for transporting heavy machinery, materials, and personnel. However, when left unmaintained, they can become difficult to navigate, especially in adverse weather conditions. One bad culvert can shut your entire site down and we’ve seen that very scenario.

What good is a 24/7/365 access guarantee if your lessees and staff can’t reach the site due to inadequate access roads and culverts? We emphasize the significance of investing in regular maintenance for your access roads. Over time, heavy usage and the forces of nature can cause substantial wear and tear, leading to costly repairs, site shutdown, and safety hazards if neglected. Frequent inspection and routine maintenance of access roads and culverts are vital to ensure their longevity and safety.

Repairs typically begin with grading the access road surface to eliminate potholes, ruts, erosion-induced washouts, or other imperfections. Depending on the road and site conditions, we may mirror the existing grade or make improvements to enhance the road. The most critical step is the subgrade, establishing the foundation for the final product. Proper compaction of the subgrade, especially when importing soil or aggregates, is essential. We compact in layers to ensure maximum stability and longevity. Installing geotextile matting separates the subgrade from base aggregates, preventing mixing and increasing stability.

Changes in pitch, flattening, crowning, and elevation changes in conjunction with the installation of culverts, water bars, swales, and ditches are options to improve road conditions and divert water away from or off the road. Materials such as road base, AB3, or crusher run are added to create a smooth, sturdy driving surface. We compact in lifts, finishing with a roller to provide reliable access to your site. Native aggregate products are obtained, crushed, and hauled by local businesses scattered throughout the American Midwest.