Why Geotextile Fabric Matters More Than You Think

Hidden beneath the rock in parking lots, access roads, and other high-use scenarios, there’s possibly one critical layer you may never see—but it can make or break your project over time: geotextile fabric.

At Reiss Earthworks, we serve telecom, residential, and commercial sites where longevity, stability, and performance matter. On sites with poor soil, heavy traffic, or long-term plans for concrete or asphalt, we often recommend geotextile fabric beneath the gravel base.

My Love-Hate Relationship with Fabric

If you have ever wanted to go sailing, grab a roll of this fabric and take it to Kansas. Start unrolling it near the top of the hill — preferably where the telecom tower is you’re working on — and real quick, you’ll be fighting with all you’ve got to keep the fabric (and yourself) grounded. That’s the hate.

The love? It saves clients money and gives you a stronger, longer-lasting surface.

The team hates working with it and regularly grills me mid-transit on which access roads have fabric… but we still roll it out on every project that needs it.

What Is Geotextile Fabric

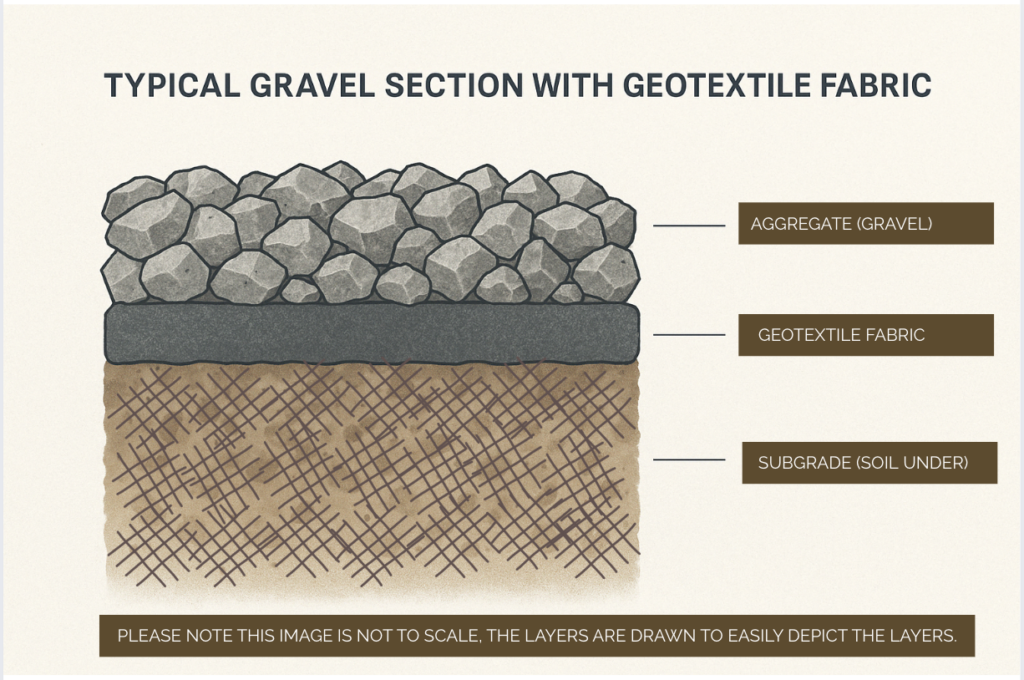

Geotextile fabric is a high-strength synthetic material installed between the natural ground (subgrade) and your base gravel. It performs four main functions:

1. Separation – Keeps your gravel from sinking into the ground

2. Stabilization – Spreads out the weight of vehicles or structures evenly across the surface

3. Drainage – Allows water to pass through without allowing soil migration

4. Reinforcement – Increases the site’s ability to resist rutting, shifting, or settlement over time, especially under repeated traffic

But not all fabric is created equal. This post explains what geotextile fabric does, which products we trust, and why it may be worth including in your project.

Understanding the Technology: Key Terms Defined

To help clarify the differences in geotextile products, here are some common terms:

Slit-Film Woven – A durable fabric woven from flat plastic ribbons. Excellent for separation and stabilization, especially over soft clay soils. Low permeability, which means water doesn’t flow through it easily. This can be helpful when water should be directed away, but problematic in wet sites with trapped moisture. Example: Mirafi 500X

High-Performance Woven – A newer style of woven geotextile that maintains high strength while also allowing water to escape both vertically (down through the gravel) and horizontally (out toward swales, ditches, or drains). Products like Mirafi HP270 and HP370 provide this dual drainage performance. This helps avoid water buildup, frost heaving, or pumping under repeated traffic.

Non-Woven – A felt-like fabric made from needle-punched fibers, commonly used in drainage and filtration systems (not under driveways or pads). It offers great water flow but lacks the strength needed for structural support.

Subgrade – The native soil beneath your construction area. In Missouri, this often includes expansive clay—a soil type that swells when wet and shrinks when dry, leading to heaving and settling.

Base Rock – The crushed stone layer placed over the fabric and compacted to create the final gravel surface or structural base.

Expansive Clay – A type of soil that swells when it absorbs water and shrinks when it dries out. This constant expansion and contraction—common across Missouri—can wreak havoc on concrete slabs, gravel surfaces, and foundation pads. It leads to:

– Uneven settlement

– Soft or pumping spots in gravel

– Cracked slabs and surface heaving

Proper soil separation and reinforcement, including the use of geotextile fabric, is one way to help mitigate these risks.

What Geotextile Fabric to Use

There is a cornucopia of geotextile fabric options out there—literally rolls and rolls to fit all kinds of site conditions and budgets. Thanks to our friends at ASP Enterprises in Kansas City, MO and the continuing education events they host, we stay current on modern options for top notch options in the construction industry.

For most of the telecom, residential and small commercial projects we build, we find ourselves installing Mirafi HP270, HP370, or 500X. These products give us a strong mix of budget-conscious options and high-performance solutions, depending on what the site needs and what the end goal is.

Our Most Used Fabrics

✅Mirafi 500X

▪️Type: Slit-film woven geotextile

▪️Best For: Driveways, gravel pads, equipment access roads

▪️Strength: High

▪️Drainage: Low

▪️Primary Benefit: Keeps gravel from disappearing into soft or muddy subgrades

✅Mirafi HP270

▪️Type: High-performance woven geotextile

▪️Best For: Parking pads, RV/trailer areas, commercial drive lanes

▪️Strength: Very high

▪️Drainage: Moderate to high (vertical and horizontal flow)

▪️Primary Benefit: Helps stabilize poor soils while managing moisture movement. Allows trapped water to escape down into the soil and laterally away from the surface.

✅ HP370 – For even greater load distribution and drainage, HP370 offers enhanced tensile strength and is suited for more extreme soil conditions, heavy commercial traffic, or deep fill applications. (and really there are so many more options)

Why Water Escape Matters

In real-world construction, especially in climates like Missouri, water doesn’t always move straight down. HP-series fabrics allow both vertical and horizontal water movement. This reduces ponding within the gravel layer, avoids freeze-thaw issues, and helps keep the base dry and stable over time—especially in areas with clay-heavy soils.

Common Misconception: Weed Barrier vs Geotextile Fabric

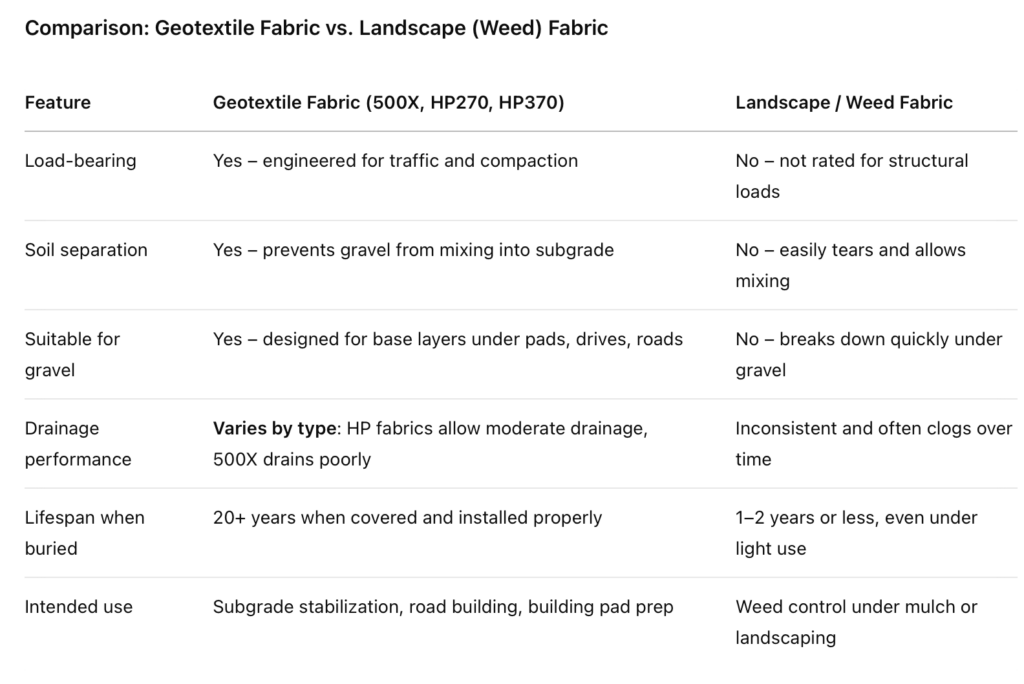

While they may look similar (pictured above), weed barrier and geotextile fabric serve completely different purposes.

Fabrics sold for landscaping or gardening aren’t designed to handle traffic, weight, or long-term exposure under gravel. If you’re unsure what’s being used, it’s always worth asking your contractor for the product type and application purpose.

When to Use Geotextile Fabric

You might consider dollar extending fabric on sites that involve:

– Soft soils

– Wet or low-lying areas

– Heavy traffic or turning movements

– Concrete or asphalt planned in the future – These surfaces require a stable base. Fabric helps prevent shifting, erosion, and long-term settlement that can damage slabs or paving.

On these jobs, fabric helps prevent:

– Rutting or washouts

– Subsurface movement

– Aggregate loss

– Unnecessary rework

Real-World Example: Our Equipment Yard

For years, our equipment yard would break down every spring. The ground would soften, gravel would mix into the mud, and we’d have to haul in new rock—every year.

In 2021, we installed geotextile matting across the lot. Since then, despite constant use from dump trucks, trailers, and heavy machinery, we haven’t added a single load of gravel. The fabric keeps the base rock where it belongs, and the lot has stayed stable through all seasons.

How Much Does It Cost

Installed, geotextile fabric typically adds 75 cents to 1.25 dollars per square foot, depending on the material and layout. On a 2,000 square foot pad or lot, expect to invest around 1,500 to 2,500 dollars.

Building a Long-Term Surface? Let’s Talk

We support landowners, contractors, companies and the utility sector improve their land, businesses, and assets they are invested in through Construction.

We can walk your site and evaluate your project if you’re building or improving:

– Access roads for telecom or other utilities

– Commercial warehouse or shop

– Detached garage or outbuilding

– Laydown lot, yard storage, or drive lane

– RV, trailer, or equipment parking lot

You’ll receive:

– A tailored estimate

– Transparent pricing and material info

– Access to our Client Portal for approvals, scheduling, and communication

Consulting with an engineer is always recommended. Their input helps ensure that your site design, materials, and layout work together to support a lasting and functional outcome.

– Cami Reiss, “Dirt Girl”, CEO & President of Reiss Earthworks

Send me a message through the contact form on my website if you’d like to discuss a project, have an idea for me to write about, have a question (dirt or business-related), or have any feedback.

Note: Our blog posts are written from within the company. Sometimes by one, sometimes by many. Sometimes, they are like a friendship quilt in which everyone puts forth effort. They are not a result of a social media manager typing into artificial intelligence asking for a 900-word blog post, followed with copy and paste and calling it good. If Cami’s writing…. sentences are sometimes long and the thoughts bounce around. If Cali’s at the keyboard, nothing will be spelled correctly for sure. And if Cadi’s typing away, you’ll get “to the point” and probably spelled correctly. Yes, a lot of C names. Needless to say, clients don’t hire us to write for them (not yet, at least. We are interested in technical writing in our industry if anyone’s looking to hire us and provide housing in a warm winter climate- Only half kidding, of course.) Thanks for showing interest. The goal is to meet clients here and assist business owners on the same journey as us if we can.

The information provided in this blog is for general entertainment and informational purposes only. It is not intended to be construed as professional advice or a guarantee of service or result. While I aim to provide accurate and helpful information, any statements, details, or pricing shared are approximate and may change based on specific project details. Reiss Earthworks does not accept liability for any inaccuracies or errors. Always consult directly with us for precise estimates or advice for your specific project.

© Reiss Earthworks LLC, 2025. All rights reserved.

Posted: